Wet pour surfacing for playground and outdoor fitness

Why surfacing matters

Wet pour rubber surfacing plays a key role in the overall experience of a playground or outdoor gym. It provides:

Consistent impact absorption

A stable, even surface for safe movement

Full accessibility for users with wheelchairs or pushchairs

A clean, cohesive look that ties the space together

Unlike loose‑fill materials, wet pour surfacing does not shift underfoot and requires minimal upkeep.

Why choose wet pour surfacing

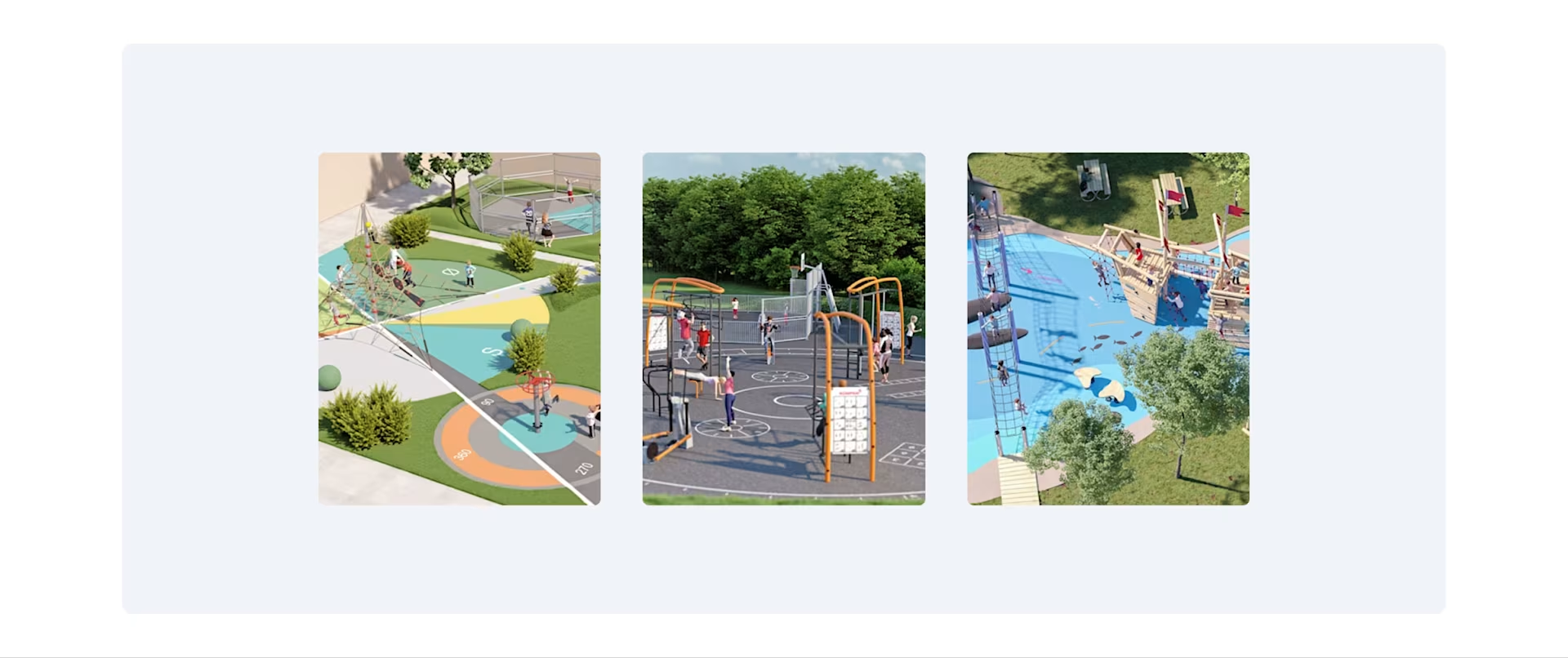

Wet pour playground surfacing is a flexible solution suitable for a wide range of public spaces. It combines the creative freedom needed for imaginative play areas with the stability and performance required in outdoor fitness environments.

Benefits for playgrounds:

Safe, cushioned fall zones

Smooth transitions between play elements

Visual structure and inclusive design

Benefits for outdoor fitness sites:

Stable footing for controlled movement

Clear zone markings for exercises

Performance that withstands repeated impact

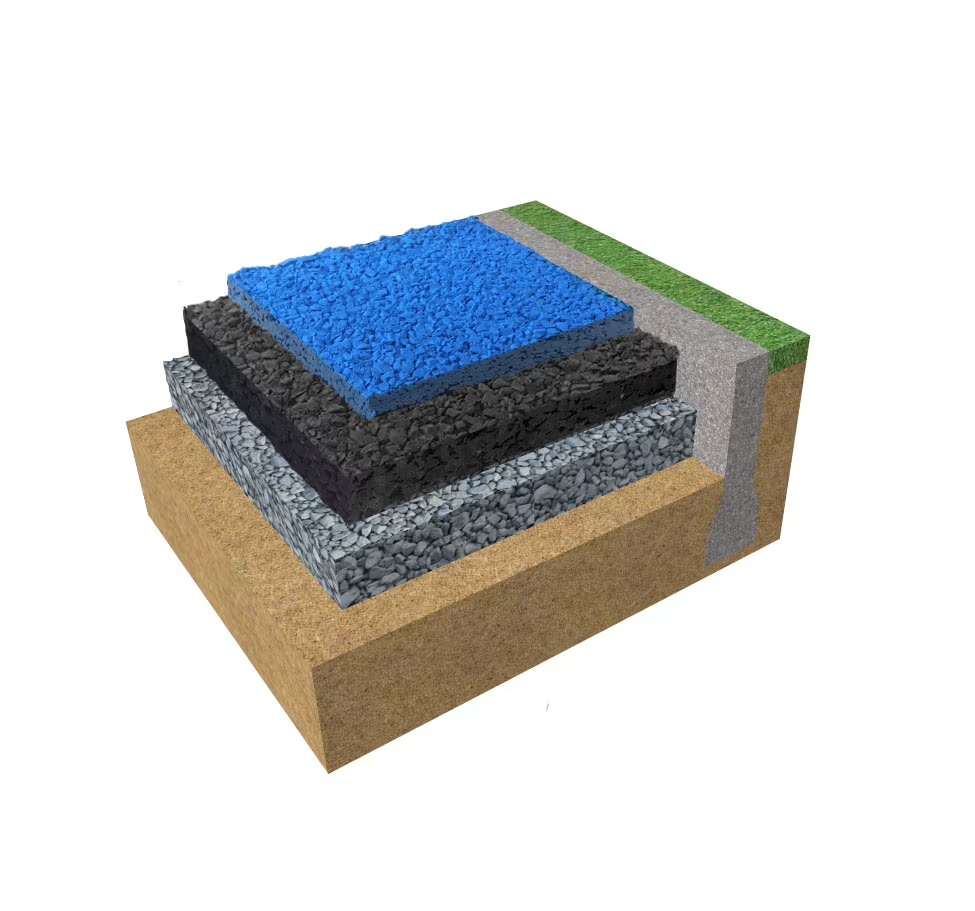

What is wet pour surfacing made of?

FLEXOTOP™ ECO is a two-layer rubber system installed directly on site. Each layer plays a specific role in delivering durability, performance and fall protection.

The top layer: A coloured EPDM rubber layer (10–15 mm) that provides long‑lasting durability, UV stability and clean aesthetics. Available in a variety of colours, including recycled‑content options.

The base layer: A shock‑absorbing layer is installed to the required critical fall height for your equipment. This is what delivers reliable impact protection. All components are designed and tested in line with AS 4685, EN 1176, EN 1177 and BS 7188 for playground safety.

Design options to enhance your space

One of the main advantages of wet pour playground surfacing is its ability to be customised. Designers can use the surface as an active part of the layout rather than a passive background.

Colours

A wide range of colours and blends to support thematic or natural designs.

Graphics

Integrated markings, shapes and simple games built directly into the top layer.

3D forms

Small mounds or sculptural elements for added visual interest or gentle play features.

Safety can also be colourful

Eggshell

SUR11118-902 | RAL 1015 *

Sand

SUR11117-902 | RAL 1011*

Bright Yellow

SUR11114-902 | RAL 1018*

Earth Yellow

SUR11113-902 | RAL 1006*

Bright Orange

SUR11115-902 | RAL 2004*

Pink

SUR11125-902 | RAL 4010*

Bright Red

SUR11106-902 | RAL 3001*

Purple

SUR11122-902 | RAL 5022*

Agua Blend

SUR11154-902

Blue

SUR11109-902 | RAL 5005*

Light Blue

SUR11108-902 | RAL 5012*

Tierra Blend

SUR11152-902

Aqua

SUR11121-902 | RAL 5018*

Teal

SUR11124-902 | RAL 5020*

Flexogrind

SUR11255-903**

Dark Green

SUR11111-902 | RAL 6005*

Green

SUR11110-902 | RAL 6017*

Sneakergrind

SUR11267-903**

Lime

SUR11120-902 | RAL 6018*

Terra Red

SUR11107-902 | RAL 3016*

White

SUR11140-902

Brown

SUR11119-902 | RAL 8011*

Light Grey

SUR11105-902 | RAL 7047*

Fuego Blend

SUR11153-902

Medium Grey

SUR11123-902 | RAL 7037*

Dark Grey

SUR11130-902 | RAL 7016*

60% Black 20% Light Blue 20% Blue

SUR11263-902

Black

SUR11101-902** | RAL 9005*

50% Black 50% Green

SUR11257-902

*) RAL-codes are only for guidance - tolerances can be expected

**) Recycled

What do you need to know before choosing your playground surface?

Our FLEXOTOP™ ECO Sneakergrind and Flexogrind have top layers made from 100% recycled material.

Recycled sneakers from production waste are shredded and can be used again for playground and fitness site surfacing. It can be mixed with other recycled materials, such as Flexogrind. Sneakers can also be mixed with 15% virgin colors.

It is very important that we reuse and recycle our raw materials. Sneakers and other are perfect for creating more eco-friendly safety surfacing and for creating circular solutions on the playgrounds and fitness sites.

Recycled sneakers can be mixed with virgin EPDM colours = 15% recycled

From an operational standpoint, FLEXOTOP™ ECO provides a clean and comfortable surface with very low maintenance costs. It's porous, with good drainage, dust-free properties, slip resistance, elasticity and hard-wearing. A uniform surface with no joints or seams, that can easily be repaired and refurbished if damaged.

Recommended care includes:

1. Removing debris such as leaves, sand, or litter

2. Sweeping the surface as required

3. Pressure washing once a year to restore porosity

Choosing the right surface depends on your project’s safety requirements, budget and design goals. Here is a short overview:

Wet pour rubber surfacing: Seamless, accessible, highly adaptable and low maintenance. Ideal for public playgrounds and fitness areas.

Rubber tiles: Easy to install, but have visible joints and limited design flexibility.

Loose‑fill (sand, gravel, wood fibre): Lower initial cost but high maintenance and limited accessibility.

Grass or synthetic turf: Natural appearance, but not suitable for higher fall heights and intensive public use.

Safety standards

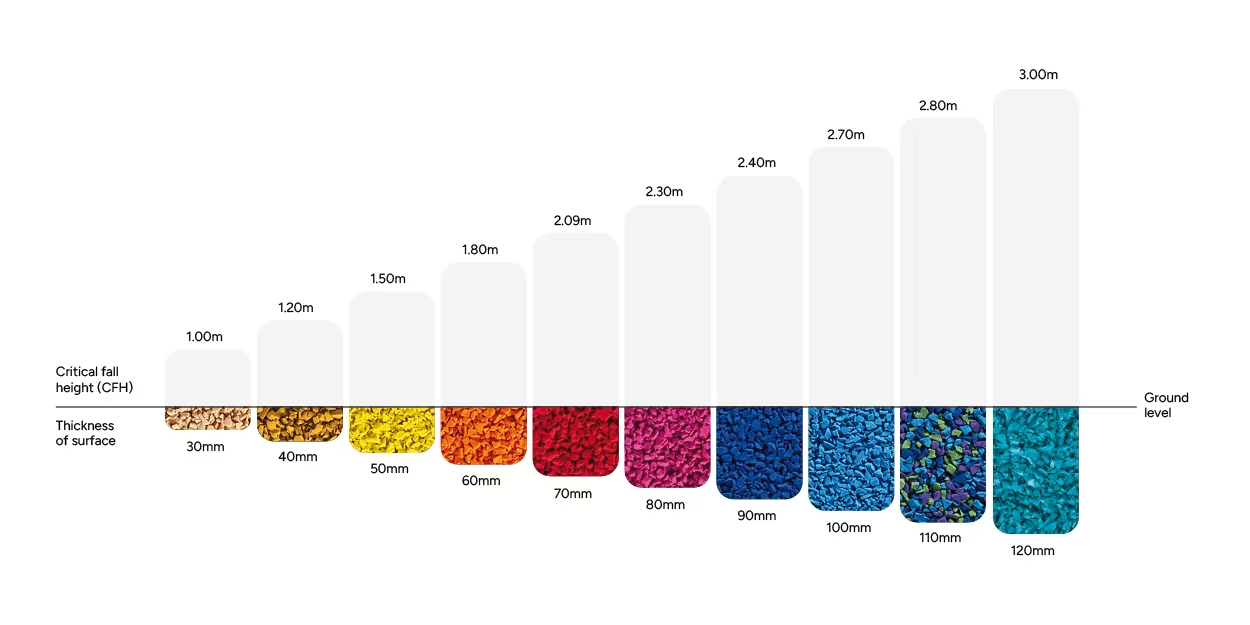

When installing playgrounds, the total thickness of the surfacing must be adjusted to the equipment's critical fall height. FLEXOTOP™ ECO is designed and tested in accordance with international safety standards, including EN 1176, EN 1177, and BS 7188.

Frequently asked questions about wet pour playground surfacing

Wet pour surfacing is a poured-in-place rubber system installed directly on site, creating a seamless, impact-absorbing foundation suitable for playgrounds and outdoor fitness areas.

When installed correctly and maintained regularly, wet pour surfacing is designed for long-term use in public spaces, resisting wear from weather and everyday activity.

The thickness of your playground surface depends on the required Critical Fall Height for the equipment in the area. Higher equipment requires a deeper base layer to meet safety standards.

If you are looking for inclusive playground surfacing, wet pour surfacing types are ideal. The seamless, firm surface supports wheelchair users, pushchairs, and users with reduced mobility, offering greater accessibility than loose-fill alternatives.

Wet pour surfacing is perfect for customisation. It allows for a wide range of colours, integrated graphics and even 3D-shaped elements built directly into the surface.

Wet pour surfacing typically requires very little maintenance. Routine sweeping and an annual pressure wash are typically sufficient to maintain its appearance and performance.